surface treatment

Aalberts surface technologies Kirchheim

about this location

welcome to Kirchheim near Munich

Since 1989, the former AHC Oberflächentechnik GmbH has been producing at its site in Munich / Kirchheim. Since 2019 we are renamed Aalberts surface technologies in Kirchheim near Munich.

We achieve our growth through constant process optimisation and the highest quality demands on ourselves. The resulting customer satisfaction confirms our performance and our daily work. We consistently invest in the further development of our plant in order to meet our constantly growing customer requirements in the future as well.

Our production offers hard anodizing with the following processes: HART-COAT® and electroless nickel plating: DURNI-COAT® (DNC) and DURNI-COAT®-AL (DNC-AL). Sealing and tempering complete our portfolio.

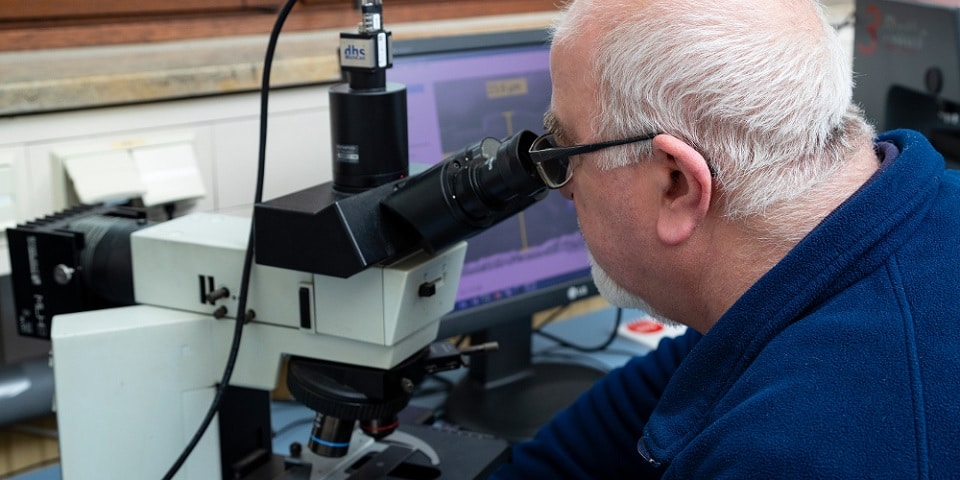

In Kirchheim near Munich we check every process carefully and have the highest demands on quality. This is also underlined by our own on-site laboratory.

“Together, our entire team develops market-driven services and new processes with the highest quality requirements, which guarantee economic success for us and our customers.“

Peter Stadler, managing director

our services in Kirchheim near Munich

process overview

| process | max. size in mm | max. weight in kg |

| Anodizing colorless (only cold) | 2800x1380x800 | 1500 |

| HART-COAT® colorless | 2800x1380x800 | 1500 |

| HART-COAT® HC-GL | 2800x550x1300 | 1500 |

| DURNI-COAT® DNC 520-AL | 1200x1000x600 | 250 |

| DURNI-COAT® DNC 571-AL lead-free | 1200x1000x600 | 250 |

| DURNI-COAT® DNC 520 | 1300x1300x620 | 1000 |

| DURNI-COAT® DNC 571 lead-free | 1300x1300x620 | 1000 |

coatings

- Hard anodizing HART-COAT®

- Electroless nickel plating DURNI-COAT®

- Technical anodizing

process services

- Analysis of material coating

- Cleaning

- Preparation, masking, covering

- Blasting with corundum

- Sealing

- Tempering

special services

- 100% control

- Assembly operations

- Technical advice and project support

- Rack construction

coating services from Kirchheim near Munich

HART-COAT® process, or HC for short, is an electrolytic treatment of aluminum, the result of which is the formation of a hard and thick aluminum oxide layer. With the HART-COAT® surface treatment we hard anodize in Kirchheim near Munich workpieces which require the highest degree of corrosion protection, wear resistance, dimensional accuracy, anti-friction behavior or insulation. HART-COAT® coatings are characterized by good adhesion to the base material. Compared to conventional anodized coatings, HART-COAT® coatings are thicker and more wear-resistant.

HART-COAT® surface finishing is used in almost all technical areas where aluminum parts are used that are subject to special functional requirements.

Suitable base materials:

HC for wrought aluminum alloys as well as sand and permanent mold cast

HC-CU for aluminum alloys with a high copper content

HC-GD for die-cast aluminum alloys

HC sealing to close the pores is usually carried out in fully demineralised water between 96 °C and 100 °C. This further increases the already good corrosion resistance of the HART-COAT® coatings.

Dry-lubricants are incorporated into the surface finish. The anti-friction properties remain intact even when the surface is subject to abrasive wear.

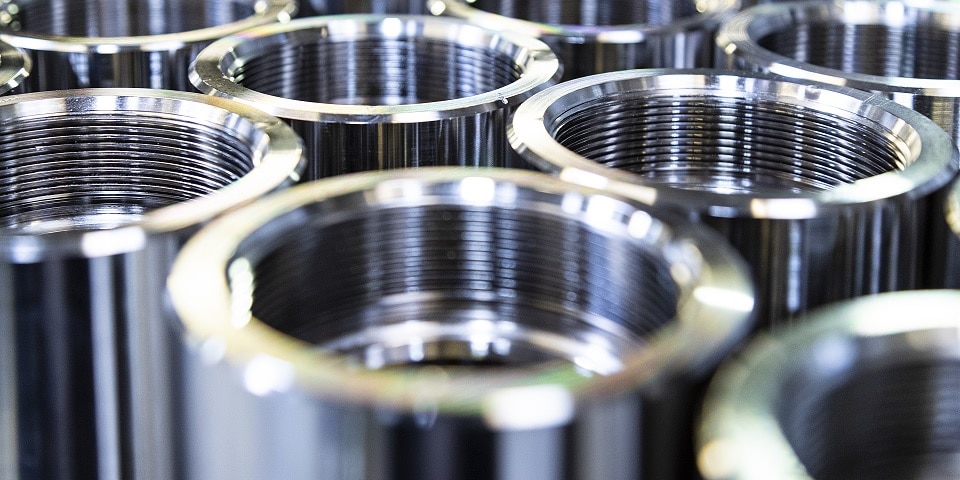

DURNI-COAT® is a process for the chemical nickel plating of metals (electroless nickel). In this process, the coating takes place as a chemical deposition without an external power source.

The performance spectrum of DURNI-COAT® coatings ranges from chemical resistance, dimensional stability and optimum sliding behavior to electrical conductivity and increased hardness. The coatings are deposited true to contour and uniformly. This ensures optimum finishing even for geometrically complex components.

The three most demanded properties when applying electroless nickel coatings are wear protection, corrosion resistance and contour accuracy. These are followed by solderability, favorable friction behavior, high ductility and certain magnetic properties.

Electroless nickel DURNI-COAT® is suitable for surface refinement of all low-alloy ferritic steels, cast iron materials, stainless steels, non-ferrous metals such as copper, brass or bronze, aluminium alloys and sintered metal materials.

Suitable base materials:

DNC 520 for iron materials and non-ferrous metals

DNC 571 for iron materials and non-ferrous metals

DNC-Al 520 for aluminum and aluminum alloys

DNC-AL 571 for aluminum and aluminum alloys

Technical anodizing is a coating for the functional, but also decorative refinement of aluminum. The coating is applied in an acid electrolyte at temperatures slightly below room temperature. The workpiece is connected as anode. In the course of the treatment, the workpiece surface is transformed into a porous (dense), hard and wear-resistant aluminum oxide layer. By sealing the pores are closed and the corrosion resistance is greatly improved. The layer thickness varies between 10 and 30 µm depending on the intended use and alloy.

Technically anodised aluminum parts offer good corrosion and wear protection in almost all industries.

quality and know-how

applications

In sum, our coatings are used wherever the following surface properties are required:

- High wear resistance

- Improved corrosion resistance

- Increase of hardness

- Optimal gliding behaviour

- Optimum layer bonding

- High thermal insulation

- High electrical insulation effect

- Good dimensional stability

- Temperature stability

fields of application

In our factory, for example, the following components are coated:

- Aluminum control plates with fine channel structures for dialysis machines

- Spacer bushes for rear wheels

- Push buttons for insulin pens for diabetics

- Guidance systems for cargo containers in the aviation sector

- Hydraulic control pins for the seat adjustment on jet boats

- Fuel pump parts

- Bearing bolts for the motor vehicle gearbox suspension of motorcycles

Let’s find a solution for your requirements!

downloads

Aalberts surface technologies offers security. We want to offer you the greatest possible security. That is why our Aalberts surface technologies sites are certified.

certificates

general terms and conditions

our inhouse processes

We are the right partner for both new parts business and component maintenance. In addition to offering anodizing, hard anodizing and electroless nickel plating, our competence also includes partial coating of components and keeping technically necessary areas of the components free from coating. In individual areas we also offer light assembly steps after coating.

industries we serve

contact & directions

Aalberts Surface Technologies GmbH